Teijin Frontier’s New High-stretch SOLOTEX® ECO-Hybrid Fiber Made with Plant-derived and Recycled Materials

MATERIALS

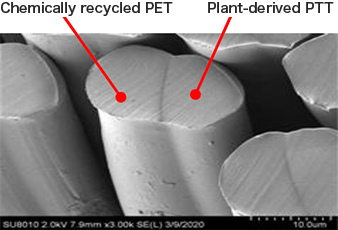

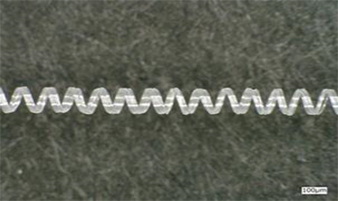

Teijin Frontier Co., Ltd., the Teijin Group’s fibers and products converting company, announced today its new SOLOTEX® ECO-Hybrid high-stretch side-by-side (S/S) conjugated fiber an eco-friendly plant-derived polymer with a chemically recycled polyester polymer, each featuring different heat-shrinkage characteristics to enable the formation of coiled crimp yarn.

SOLOTEX® ECO-Hybrid represents a new line in Teijin Frontier’s polytrimethylene terephthalate (PTT) fiber SOLOTEX® family. SOLOTEX® ECO-Hybrid filament yarn and textile will be introduced as a featured product for 2020 autumn/winter fashion apparel, offering many possibilities for enhanced sportwear, uniforms and more. Annual sales of SOLOTEX® ECO-Hybrid are expected to grow from JPY 500 million in 2020 to JPY 1.5 billion in 2022 (filament yarn equivalent).

|  |

| Polymers | Extra stretchability achieved with new technology for conjugating PTT polymer and polyethylene terephthalate(PET) polymer made with chemically recycled raw material, which are then processed to create a crimp structure. |

| Filament Production | Crimp structure is equivalent to that of petroleum-derived raw materials. Dyeability achieved with optimized yarnmaking conditions. |

|  |

| Eco-friendly | PTT polymer is partly made with plant-derived raw materials and PET polymer is made with chemical recycled raw materials such as used polyester fibers. |

| Versatile fineness | Wide range of fineness, from 33-330dtex, and filament yarn processing is possible. |

| Highly practical | Very stretchable and dyeable, equivalent to those of petroleum-derived materials, and soft texture. |

SOLOTEX® ECO-Hybrid has the same features as conventional S/S conjugated fiber made with petroleum-derived raw materials.

In recent years, demands have been growing for materials offering functionality and comfort, such as stretchability and soft textures. Also, users are seeking eco-friendly fabrics made with recycled and plant-derived materials.

Teijin Frontier’s existing S/S conjugated fiber comprises a highly stretchable SOLOTEX® PTT-fiber polymer made with about 40% plant-based raw materials and PET made of recycled raw materials. The newest version, SOLOTEX® ECO-Hybrid, solves the problem of achieving a consistent crimp structure in an eco-friendly S/S conjugated fiber made with recycled PET.

About the Teijin Group

Teijin (TSE: 3401) is a technology-driven global group offering advanced solutions in the fields of environmental value; safety, security and disaster mitigation; and demographic change and increased health consciousness. Originally established as Japan’s first rayon manufacturer in 1918, Teijin has evolved into a unique enterprise encompassing three core business domains: high-performance materials including aramid, carbon fibers and composites, and also resin and plastic processing, films, polyester fibers and products converting; healthcare including pharmaceuticals and home healthcare equipment for bone/joint, respiratory and cardiovascular/metabolic diseases, nursing care and pre-symptomatic healthcare; and IT including B2B solutions for medical, corporate and public systems as well as packaged software and B2C online services for digital entertainment. Deeply committed to its stakeholders, as expressed in the brand statement “Human Chemistry, Human Solutions”, Teijin aims to be a company that supports the society of the future. The group comprises more than 170 companies and employs some 20,000 people across 20 countries worldwide. Teijin posted consolidated sales of JPY 853.7 billion (USD 8.0 billion) and total assets of JPY 1,004.2 billion (USD 9.4 billion) in the fiscal year that ended on March 31, 2020.

Please visit www.teijin.com.

Press ContactCorporate Communications

Teijin Limited

+81 3 3506 4055

pr@teijin.co.jp